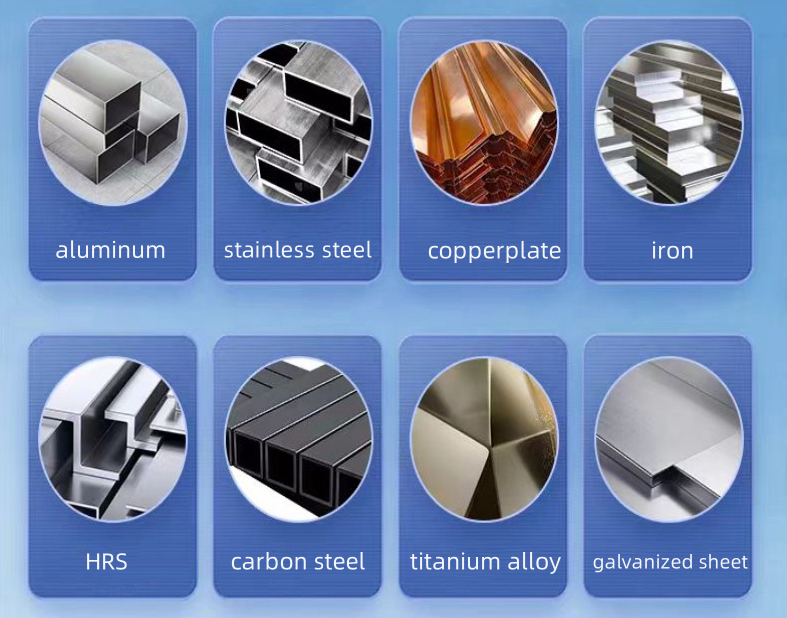

1. Ke kila kila

He kiʻekiʻe ka nui o ka hoʻonui ʻana o ke kila kila, a ua maʻalahi i ka overheating i ka wā wili. Ke liʻiliʻi iki ka wahi i hoʻopilikia ʻia i ka wela, e hoʻopilikia ʻia ka deformation koʻikoʻi. Eia naʻe, haʻahaʻa ka wela i hana ʻia e ka mīkini wiliwī laser paʻa i ka wā o ke kaʻina hana kuʻi. Hoʻohui pū me ka haʻahaʻa haʻahaʻa thermal conductivity, kiʻekiʻe ikehu absorption rate a me ka hoʻoheheʻe ʻana i ka maikaʻi o ke kila kila, maikaʻi-hana, ʻoluʻolu a nani nā welds hiki ke loaʻa ma hope o ka wili.

2. Ke kila kalapona

Hiki ke hoʻopaʻa lima ʻia ke kila kalapona maʻamauMīkini wiliwili laser fiber, Hoʻohālikelike ka hopena me ke kila kila, a ʻoi aku ka liʻiliʻi o ka wahi i hoʻopili ʻia i ka wela, akā i ka wā e wiliwili ai i ka medium a me ke kila kalapona kiʻekiʻe, ʻoi aku ka kiʻekiʻe o ke koena o ke koena, no laila pono e hoʻopaʻa ʻia ma mua o ke kuʻi ʻana. ʻO ka hoʻomaʻamaʻa ʻana a me ka mālama ʻana i ka wela ma hope o ke kuʻi ʻana e hoʻomaha i ke kaumaha a pale i nā māwae. Maanei hiki iā mākou ke kamaʻilio e pili ana i ka mīkini wiliwili anu. Hiki ke wiliwili ʻia a hoʻoponopono ʻia paha ke kila kalapona liʻiliʻi a me ke kila kiʻekiʻe me ka wiliwili anu a me ka uwea wili hao. Ma keʻano o ka mālamaʻana i ka mahana, ka hoʻomaluʻana i ka mahana, a me ka hoʻomaluʻana i ka mahana, hiki i ka mīkini wiliwili anu ke aʻo i ka hoʻopaʻa lima laser iʻoi aku ka maikaʻi ma ke koena wela ma hope o ka hoʻopiliʻana.

3. Make kila

He kūpono ia no ka wiliwili ʻana i nā ʻano kila make, a maikaʻi loa ka hopena kuʻi.

4. Aluminum a me ka alumini

ʻO nā alumini alumini a me nā alumini nā mea hoʻomanaʻo nui, a hiki ke ʻike ʻia ka porosity i loko o ka loko i hoʻoheheʻe ʻia a i ke kumu paha i ka wā wili. Ke hoʻohālikelike ʻia me nā mea metala mua, ʻoi aku ka kiʻekiʻe o nā alumini alumini a me nā alumini no nā ʻāpana, akā i ka wā e kūpono ai nā ʻāpana welding i koho ʻia, hiki ke loaʻa ka weld seam me nā ʻano mechanical like me ka metala kumu.

5. Ke keleawe a me ke keleawe

He ikaika loa ka conductivity thermal o ke keleawe, a he maʻalahi ke kumu i ke komo ʻole ʻana a me ka fusion hapa i ka wā wili. ʻO ka mea maʻamau, hoʻomehana ʻia ka mea keleawe i ka wā o ke kaʻina hana kuʻi e kōkua i ka wili. Eia mākou e kamaʻilio nei e pili ana i nā mea keleawe lahilahi.Mīkini wiliwili lima limahiki pololei Welding, no ka mea o kona ikehu a me ka wikiwiki kuʻihao wikiwiki, ua emi i ka hopena e ka kiʻekiʻe thermal conductivity o ke keleawe.

6. Welding ma waena o nā mea like ʻole

Hiki ke lawe ʻia ka mīkini hoʻoheheʻe lima lima ma waena o nā ʻano metala like ʻole, e like me ke keleawe-nickel, nickel-titanium, copper-titanium, titanium-molybdenum, brass-copper, low carbon steel-copper a me nā metala like ʻole. Hiki ke hoʻokō ʻia ka welding laser ma lalo o nā kūlana (gas a i ʻole ka mahana).

Mīkini wiliwili lima limai kēia manawa he huahana i hoʻohana nui ʻia i ka ʻoihana wili, ʻoiai ʻoiai ʻoi aku ka nui o ke kumukūʻai o kēia mea hana, hiki iā ia ke mālama maikaʻi i nā koina hana. He pipiʻi ke kumukūʻai hana o nā welders. Ke hoʻohana nei i kēia ʻO ka huahana e hoʻonā i ka pilikia o ka loaʻa kālā a paʻakikī o nā welders. Eia kekahi, ua lanakila ka mīkini hoʻoheheʻe lima lima i ka mahalo nui mai nā tausani o nā mea kūʻai aku ma muli o kona ola lōʻihi a me ka hoʻohana haʻahaʻa haʻahaʻa.

Inā makemake ʻoe e aʻo hou e pili ana i ka hoʻomaʻemaʻe laser, a makemake paha e kūʻai i ka mīkini hoʻomaʻemaʻe laser maikaʻi loa no ʻoe, e ʻoluʻolu e waiho i kahi leka ma kā mākou pūnaewele a leka uila pololei iā mākou!

Ka manawa hoʻouna: Dec-25-2024